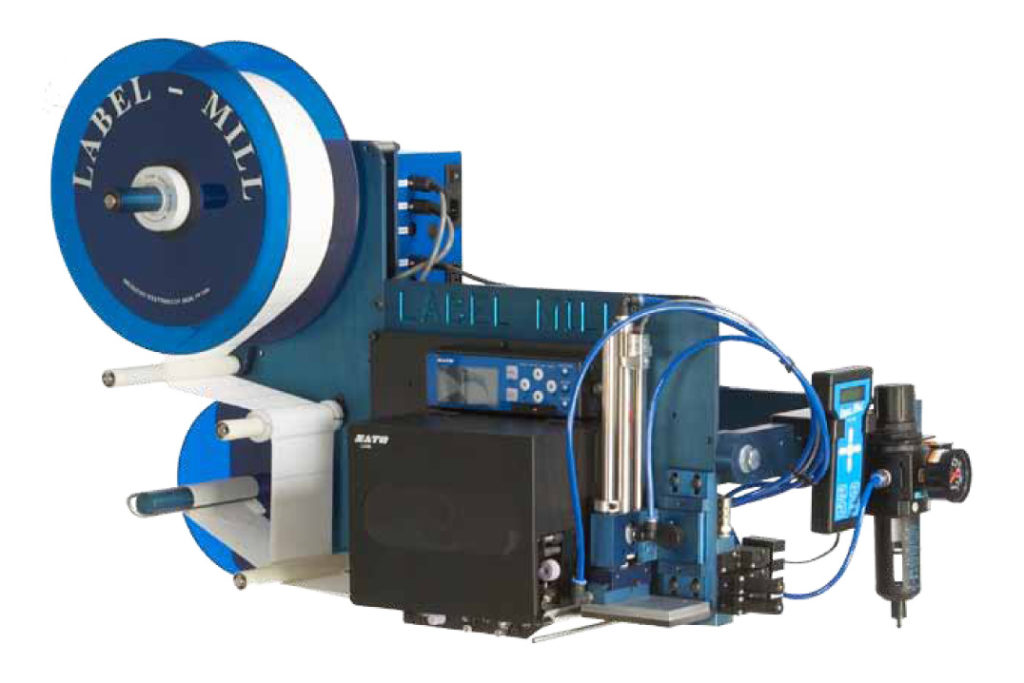

Equipment Labeling & Inkjet Printing Label Mill Label Applicators Label Mill LM3605 Automatic Print and Apply System

Label Mill LM3605 Automatic Print and Apply System

Key Features

Overview

The Label Mill LM3605 print and apply labeling system has a modular design that allows for quick in plant modifications to meet your needs.

Controller software for this label printer applicator is user friendly and password protected. Several standard features available such as: easy to enter selections, a large touch pad and back lit display.

With easy setup, the 3605 hand-held labeler allows adjustments of product delay, tamp duration, cycle type and other key functions. System is available in both right-hand and left-had designs.

Features

Label Mill 3605 Features:

- Heavy Duty Industrial Design

- 12 Inch Label Storage Spool Standard

- Swing Away Tamp Assemble

- User-Friendly Operating Software

- Batch Counter

- Printer Status Outputs

- Left and Right-Hand Designs

- Hand Held User Interface

Additional Options:

- System Status Light Tower

- Smart Tamp

Specifications

Label Mill 3605 Specifications:

- Print Speed/Rate: Up to 16″ per second. Approximately 10-90 per minute, depending on label and product size.

- Print Method: Thermal transfer and direct thermal

- Interface: Centronics parallel, RS-232c Serial, Ethernet, Wireless and USB

- Application Method: Tamp is standard Wipe-on, blow, corner-wrap, and adjacent panel are optional

- Bar Codes:UPC-A, UPC-E, EAN-8, EAN-13, CODE 3912/5, CODE 128, CODABAR, MSI 2/5, CODE 93, UPC Bookland, Matrix 2/5, POSTNET, UCC/EAN 128, PDF-417, Maxicode, Data Matrix

- Bar Code Ratios: 1:2, 1:3, 5:2

- Interface Sensors: Product sensor-photo eye/limit switch/PLC input Auxiliary output with connector standard

- Electrical: 115 VAC/60Hz – 250 W idle, 600 running

- Human Readable Fonts: 12 proportional and mono-spaced fonts including OCR-A and OCR-B representations and an outline font. American and European characters, uppercase and lower case with descenders (code table 850)

- Air Requirements: 80 psi/3 cfm when equipped with tamp, flag, blow, swing, and corner wrap

- Environment: Operating 50-95° F (10-35° C) 15-85% RH, non-condensing

- Label Size: Minimum 1” wide x 1/2” long Maximum 4” wide x 14” long

- General Size: 32”W x 24”D x 24”H

- Weight: 61 lbs. with u-arm

- Label Roll Capacity: 12” maximum outside diameter wound on a 3” I.D. core. Die-cut waste removed with minimum of 1/8” separations between labels in running direction.

- Additional Options: Right and left-hand models. Sato, Zebra, Datamax, OEM Printers.

Maintenance

Shorr Packaging stands behind all the packaging equipment we represent, with a service network that extends throughout the contiguous U.S.

Our packaging automation specialists offer complete support for equipment selection, integration, installation, training, maintenance, 24/7 emergency service and parts procurement.

All of Shorr’s service technicians are factory certified and dedicated to ensuring that your packaging equipment is always operating at peak performance.