Shorr Packaging Corp. recently had a food packaging customer in need of a solution that would double their production through packaging automation and keep their employees safe from virus transmissions. With 100 years of experience serving customers in the food segment, we were up for this unique challenge.

A Manual Make-over

Food packaging is unique compared to other material packaging segments because you have the added challenge of keeping perishable items sealed and fresh. Materials like glass, metal, paper and paperboard are used to ensure that food does not go to waste from the moment it hits the store shelf to the extended period of time it is in the home of the consumer.

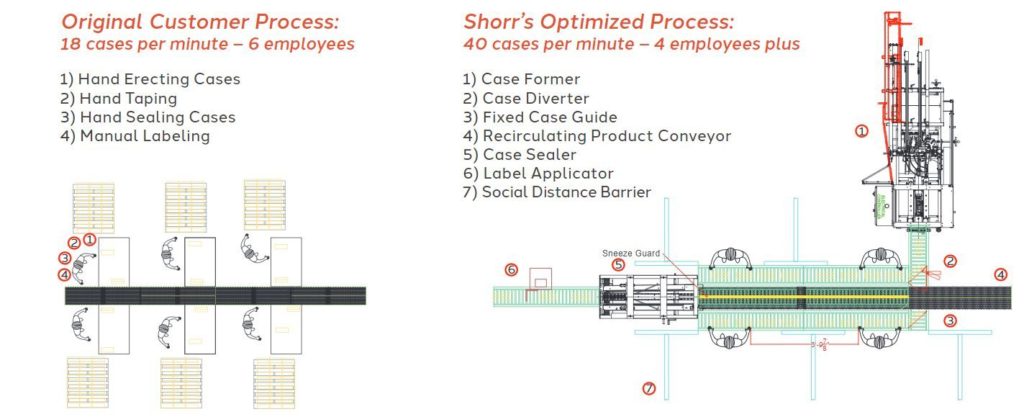

The customer’s original packaging process included hand erecting cases, hand taping, hand sealing cases and manual labeling. This manual process was complicated and inefficient, taking six laborers at a time to produce 18 cases per minute. On top of that, the six laborers were unable to practice social distancing in the wake of the Covid-19 Pandemic.

A New Workflow

We helped them achieve their safety and efficiency goals by implementing packaging automation, a process or procedure of packaging a product without human assistance. Packaging automation can range from one piece of equipment to entire automated packaging systems. In this case, we completely redesigned their workflow process.

Automation Innovation

We began by recirculating the product conveyor and using our top of the line automated food packaging equipment to build and convey cases to employees. Using a case former, case diverter, fixed case guide, recirculating product conveyor, case sealer, label applicator, and social distance barrier, we were able to optimize the process. This process now allows employees to pick a product and place it into the cases, which are conveyed to the automated case sealer. Cases are then closed, sealed, and labeled.

We also implemented social distancing by reducing the number of employees from six to four without losing out on productivity. In fact, with the new automation equipment in place, productivity increase from 18 to 40 cases per minute; more than doubling production output. In addition to CDC recommended social distancing practices, we also implemented sneeze barriers to further prevent the spread of Covid-19. A sneeze barrier is a transparent, often plexiglass barrier, that prevents the spread of airborne germs from coughing and sneezing without inhibiting interaction between people.

Unparalleled Production

Upon conclusion, we increased our customers’ production by 120% and were able to redeploy two employees to other responsibilities. We also safeguarded the warehouse with social distancing techniques and sneeze barriers to keep employees safe from the Covid-19 Coronavirus.

Shorr’s packaging automation design team will support your food company’s growth and transformation during this challenging time. Bring us your challenges and operational goals. We’ll work with you to design an automated solution that improves your workflow.

Shorr is a premium, full-service packaging partner with an unmatched ability to optimize holistic supply chain processes, differentiate brands from their competition, and accelerate client growth. Our comprehensive programs, integrated solutions, and automated packaging systems will transform your packaging operation by holistically addressing all areas of packaging—from design through inventory and life-cycle management.